Seable&Co is specialist outfitting company of superyachts, and premium residential, and hospitality properties. Each with its own expertise as well as complementary, our divisions can deliver a wide scope of bespoke features contributing to the user experience. We take pride in creating the finest bespoke spa areas, swimming pools, marble finishings, exterior furniture, decking, specialist owners' supply, and much more. By constantly challenging the status quo for superyacht essentials, we continually surprise superyacht owners, owner representatives, designers and shipyards with new possibilities. Through close collaboration with designers and shipyards, we have already introduced several innovative solutions to our clients.

Owner’s experience

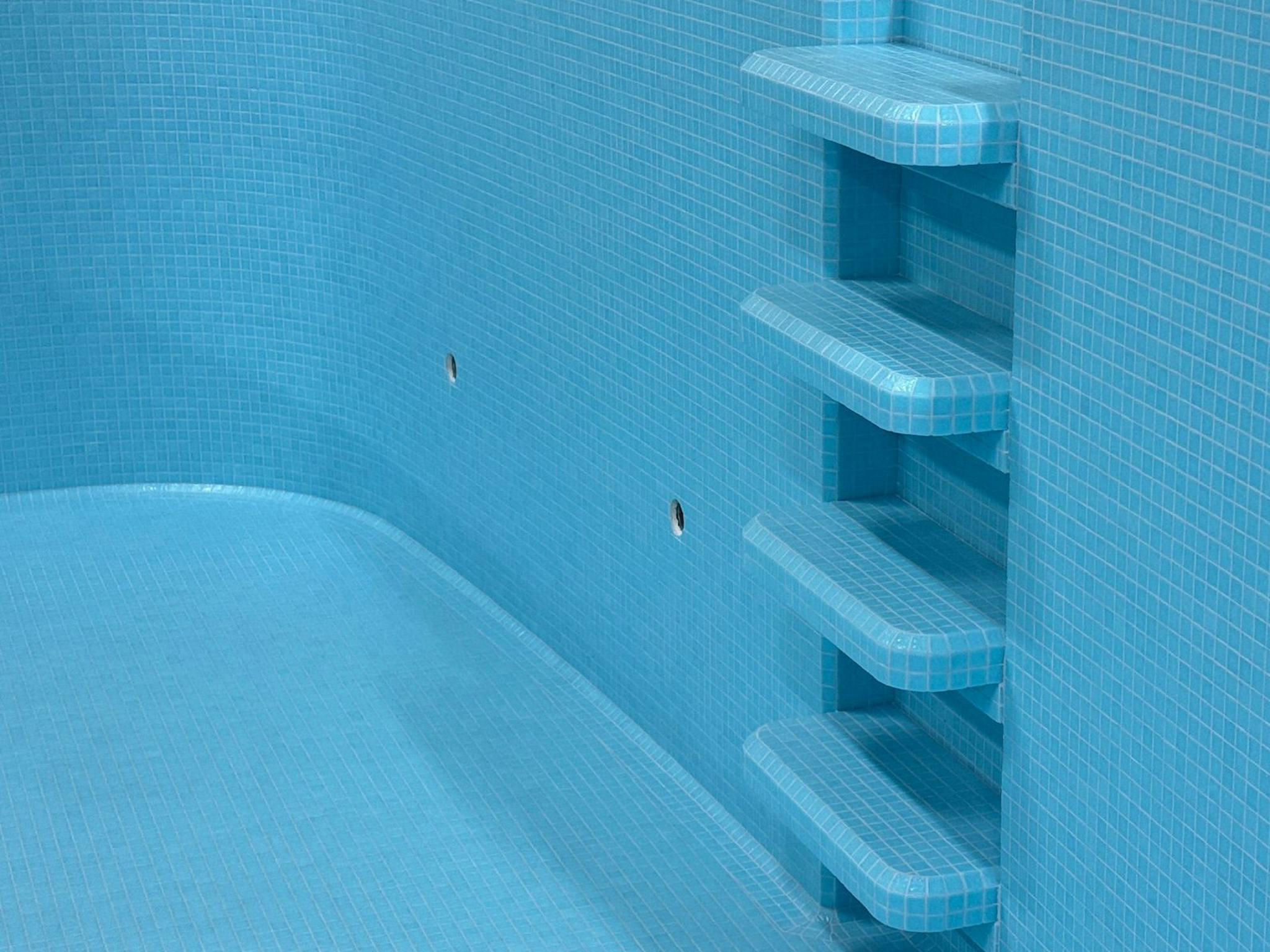

Our primary focus is the owner’s experience on board. We exist at the intersection of craft and innovation, drawing on time-honoured artisanal know-how along with modern ingenuity and technology to create the finest bespoke spa areas, swimming pools, marble fittings, exterior furniture and decking, and much more.

Combined experience

As a collective we have over 80 years of combined experience. The strength of our past is what carries us forward into the future, but we encourage our clients to continually challenge us and push the boundaries of what is possible.

Our Approach

Ever attentive to customer needs and requirements, our interdisciplinary team approaches each project afresh and fully supports clients during the transition from vision to reality. We ensure the desired results are achieved by being involved in each step of the project from concept to construction and beyond.

Innovation

By challenging the status quo, Seable&Co continues to surprise our clients with new possibilities. And by investing in new production technologies, we provide our craftsmen with the tools to further focus on their core skills.

Craftmanship

Along with our uncompromising dedication to excellence, it takes skill, talent, years of experience and passionate teamwork to process the finest materials in wood, stone and other natural materials.

Collaboration

Every collaboration should be based on shared values and ambitions in combination with complementary skills. In this way, we can continue to inspire and challenge ourselves – and surprise our clients with the outcomes.